Wood Cad Cam Software

Challenge To keep ahead of their competition and serve its expanding markets, the company requires the latest advances in equipment and software to produce these unique products. Solution. Benefits. Mastercam allows the wood designers great flexibility to produce the desired wood shapes and contours they need. Mastercam's Backplot and Verify features ensure there are no machine crashes. Mastercam's surfacing toolpaths – being able to control the tool in a 5-axis curve with line contro.l. Mastercam's axis limitations feature is very helpful to the shop.

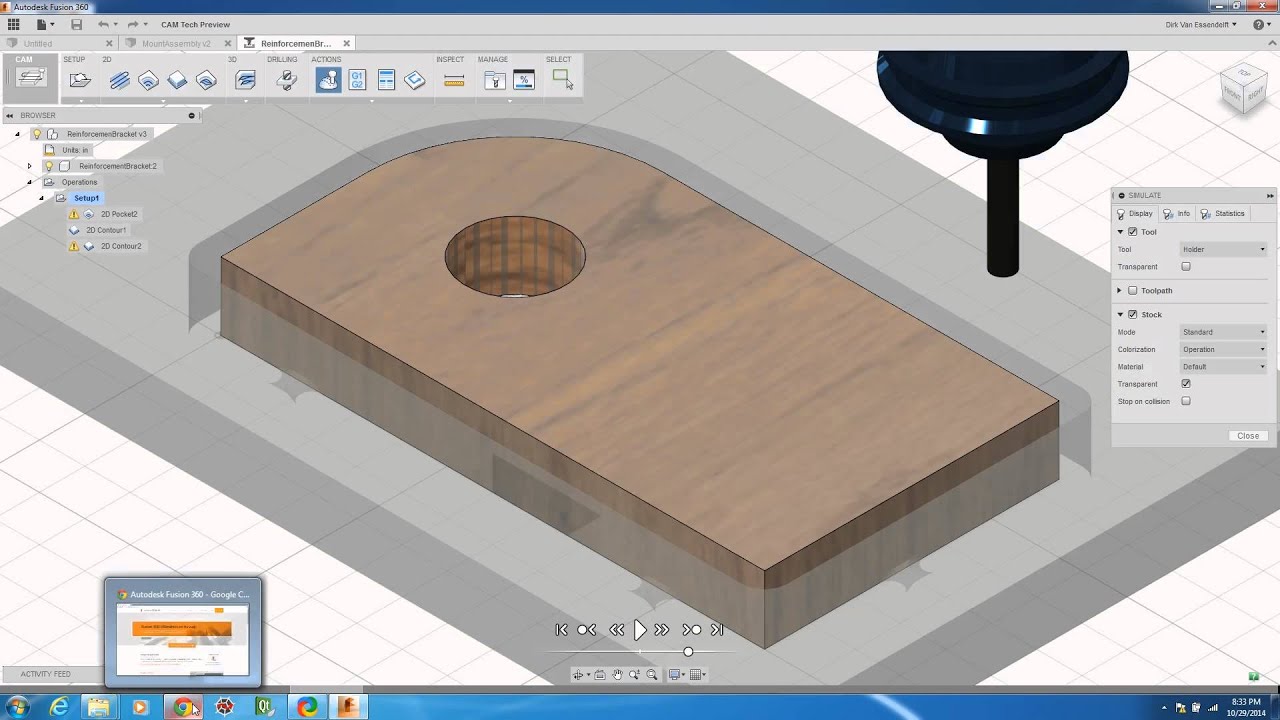

The woodworking industry is vast and requires powerful CAD-CAM solutions for designing wood products and then CNC machining them. BobCAD-CAM is a popular solution for creating custom specialty products, sign-making, furniture and much more. Total CAD/CAM Solution for the Woodworking Industry 30 Day No Obligation Free Trial. Try a leader in wood working CAD software for yourself with a 30 day, no obligation, free trial. Just fill in the form and we will be in touch. Wood CAD/CAM Features. Industry focused automation. WoodCAD CAM is the software for furniture and interior design. Whether standalone furniture or complex room designs - the entire process from the first draft to the finished product is as simple as it is impressive. By mouse click, production drawings and bills of material are immediately available after finishing the design.

Support on the Mastercam forum, and it is very easy to use. Burns Wood Products in Granite Falls, NC manufactures shaped plywood for manufacturers that need curved doors, drawer fronts, table aprons, primarily any products where bowed plywood can be used in its production. They provide ready-to-assemble products to the marine, home interior, toy, and leisure markets. They'll also produce other custom wood products, just about anything that will fit within their wood-working capabilities. With 40 employees and 40,000 sq.

Of manufacturing space, the 25-year-old company produces part quantities from 15 to 2,000. To produce unique shapes in wood, the company recently added two five-axis router machines and one three-axis machine.

To control these machines, they use Mastercam CAD/CAM software that allows the wood designers great flexibility to produce the desired wood shapes and contours they need. After designing the component, the information is downloaded to the routers to produce the parts. Wood is cut by the router as thin veneer strips called plies that are put through a glue spreader, pressed together, and built up layer by layer to get the desired thickness for the final production part. Then they are placed in a workholding fixture that consists of a top and bottom block shaped to the final form of the part and a vacuum fixture to hold down the wood. The workholding fixture along with the wood is then moved into a radio-frequency press, like a giant microwave oven, that uses microwaves to dry the wood. These vacuum workholding fixtures are made by the company and are also produced using the routers.

Steam bending, which at times is used to bend wood, is not used by the company, says Programmer Travis Buchanan. For surfacing Buchanan says, 'When we do simple curved plywood as well as ones using compound angles, I need to mill those vacuum fixtures so the part seats properly in a particular location. I might be milling a vacuum jig in the shape of a human face for instance. In fact, if you're sitting in an office chair right now, you most likely have a curved-plywood back inside that upholstery, and I'd machine those parts in that seat. I also machine all of the press forms that we press those parts in. Those surfaces are milled out on the router.'

Wood Cad Cam Software For Hobby

Buchanan mentions that two features that he uses that are very important to him in Mastercam are Backplot and Verify. He uses them to make sure he doesn't have a crash. He also likes the surfacing toolpaths in Mastercam. 'I really like the five-axis toolpaths that are available. Being able to control the tool in a five-axis curve with line control has been a real useful feature for me. I like the fourth-axis buttons that I can lock the machine down to a four-axis cut. I really think the axis limitations was an efficient feature that Mastercam added.

If I need to machine something, and say the knuckle on my five-axis is going to hit, then I can just tell it to not let the A-axis go over 45 degrees, and modify the toolpath to hold that 45 degree angle with the A-axis.' Buchanan also mentions that there is a lot of support from Mastercam, including the Mastercam forum, and it's all easy to use.

'It does the job for me,' he adds. With the addition of the CNC routers, Mastercam, and a digitizer, Burns Wood Products can now give its customers optimal choices to develop products and shorten lead times. The company's goal is to continue to study technological advances and add them as necessary to stay ahead of the competition and give its customers quality products.

Woodwork for Inventor (W4I with CAM) includes tools to automatically generate CNC code directly from your Inventor models! Yes that's right, Automatic CNC tool path generation for furniture design! A great deal of CNC programming for Joinery and cabinet making is straightforward. Machining holes in panels isn’t complicated, the trouble is that we have so many panels to do!

Unfortunately even ‘Standard’ panels that are tweaked each time we use them still require a new CNC program every time. Programming the same old parts over and over again is time consuming, boring and prone to error. CNC programing represents a stop point in our design process. If there is a last minute design change, the CNC programmes must be written again from scratch – oh no! For this reason, CNC can become a real pre-production bottle neck. A process that we don’t enter into lightly and one that we daren’t stop once it’s in process. Woodwork for Inventor takes away a lot of the headache and helps us by running an automatic algorithm over our design, picking out parts that can be CNC’d and generating programme files automatically.

With no apparent effort from us! Figure 1 CAM generation. Step one, check to see if CAM files have been generated already. Figure 2 Step Two, create the CNC information. Figure 3 Step Three, Generate the CNC files. Figure 4 CAM generation. The CNC information has been generated and added to the part file.

An MPR file has been generated for Woodwork. In addition, Woodwork for Inventor with CAM can link the CNC file to the part, giving us a visual clue over which parts have been generated. This link also helps the CNC files to be ‘pulled’ into Vault, giving us a place to manage all of our CNC data. The software automates a tedious process, allowing us to work quicker, react to late design changes better and eliminate errors from our work process. Woodwork for Inventor with CAM supports post-processors for the following systems:. Hops (.hop).

BiesseWorks (.cix). WoodWOP (.mpr).

Best Cad Cam Software

AlphaCAM (.dxf). CNI Informatica (.cni). AutoCAD (.dxf). TpaCAD (.tcn). EdiCAD (.tcn).

IMAwop (.fmc). MasterWood (.tlf). TwinCAM (.dxf) To find out more about the fantastic CAD/CAM features in this Furniture design software add-on click on the link below.